In today’s hyper-connected world, cables serve as the backbone of modern infrastructure, powering industries, enabling communication, and supporting technological advancements. From automotive wiring harnesses to high-voltage energy transmission and fiber-optic networks, the demand for durable, efficient, and high-performance cables is higher than ever.

At Delta Tecnic, a global leader in cable masterbatch innovation, we specialize in developing advanced masterbatch solutions tailored to meet the stringent technical, safety, and aesthetic requirements of the wire and cable industry.

This blog explores how Delta Tecnic’s cable masterbatch solutions enhance performance, compliance, and sustainability in automotive, energy, and telecom applications.

Page Contents

- 1 What is a Cable Masterbatch?

- 2 Key Components of a Cable Masterbatch

- 3 Delta Tecnic’s Expertise in Cable Masterbatch Solutions

- 4 Masterbatch Solutions for the Cable Industry

- 5 Applications of Delta Tecnic’s Cable Masterbatches

- 6 Why Choose Delta Tecnic for Cable Masterbatch?

- 7 Elevate Your Cables with Delta Tecnic

What is a Cable Masterbatch?

A cable masterbatch is a concentrated blend of pigments, additives, and carrier resins designed to impart specific properties to cable insulation and sheathing.

Key Components of a Cable Masterbatch

- Pigments – Ensure precise color coding and opacity for easy cable identification.

- Additives – Provide UV resistance and protection against environmental stressors.

- Carrier Resins – Optimize compatibility with PVC, PE, LSOH (Low Smoke Zero Halogen), and other base polymers.

At Delta Tecnic, our cable masterbatch solutions are developed to meet international safety and quality standards, while also addressing industry-specific challenges.

Delta Tecnic’s Expertise in Cable Masterbatch Solutions

- As a technology leader in color and additive masterbatches, Delta Tecnic delivers high-performance solutions aligned with global standards such as:

- RAL, MUNSELL, EIA359, SAE J 1128, and NEMA color codes.

- RoHS & REACH compliance for environmental and safety regulations.

- Custom formulations for industry-specific applications.

Our Technology-Driven Approach Ensures:

- High Pigment Concentration – Dosages as low as 1%, reducing material costs without compromising color intensity.

- Thermal Stability – Masterbatches engineered to withstand extreme temperatures and aging tests.

- Color Uniformity – Ensuring consistent hues across large-scale cable production for safety and compliance.

- Precision-Engineered Pellets – Optimized for high-speed extrusion, ensuring seamless processing.

Masterbatch Solutions for the Cable Industry

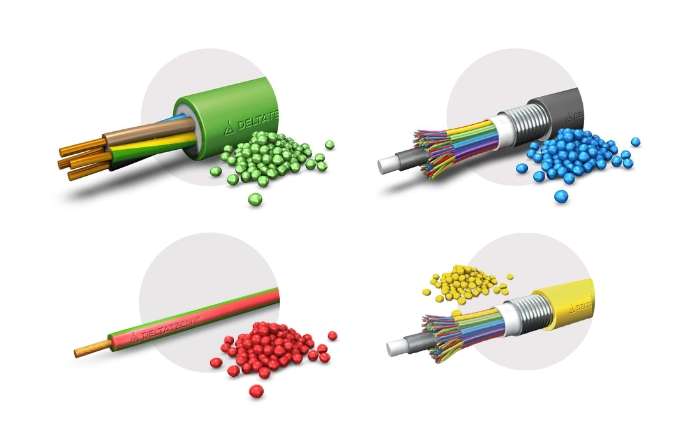

At Delta Tecnic, we offer a comprehensive range of cable masterbatches, categorized into specialized product lines to meet distinct processing and application requirements.

-

PVC-Based Masterbatches for the Cable Industry

-

DELTAVINIL SP (Standard Pellet)

- Base Polymer: PVC

- Applications: Cables, profiles, pipes, and films.

- Features: Ensures excellent dispersion and color consistency, ideal for general-purpose cable insulation and sheathing.

-

DELTAVINIL MP (Micropellet)

- Base Polymer: PVC

- Applications: Cables, profiles, pipes, and films.

- Features: Micropellet format improves dilution efficiency, ensuring homogeneous mixing and uniform color distribution.

-

DELTAVINIL SMP (Small Micropellet)

- Base Polymer: PVC

- Applications: Rigid PVC cables, pipes, and compounds.

- Features: Ultra-fine micropellets enable rapid dilution and flawless homogeneity, perfect for high-speed extrusion.

-

-

Polymer-Specific Masterbatches for Advanced Cables

-

DELTAPLAST SP (Standard Pellet)

- Base Polymers: PE, PP, EVA, TPE‑E, PBT, PA, TPU.

- Applications: Cable insulation and sheathing for diverse polymer bases.

- Features: Spherical pellet design improves dosing accuracy and color consistency.

-

DELTAPLAST MB (Micro Bead)

- Base Polymers: PE, EVA.

- Applications: Cables requiring exceptional color uniformity.

- Features: Micro bead technology enhances color homogenization, ideal for automotive wiring and telecom cables.

-

Applications of Delta Tecnic’s Cable Masterbatches

-

Automotive Cables

- Thermal Resistance – Withstands temperatures up to 150°C in engine compartments.

- High-Speed Extrusion Compatibility – Designed for ultrathin wall cables processed at 1,200 m/min.

- Regulatory Compliance – Phthalate-free, heavy metal-free formulations meeting RoHS, REACH, and OEM standards.

-

Energy Cables

- Dielectric Integrity – Pigments designed to maintain insulation properties.

- Low & Medium Voltage Solutions – Ideal for solar panels, robotics, and smart grids.

- Flame Retardancy – LSOH formulations reduce smoke emissions in case of fire.

-

Telecom & Fiber-Optic Cables

- High Opacity – Ensures clear identification in high-density cable bundles.

- Signal Integrity – Pigments that do not interfere with data transmission.

- Superior Dilution Efficiency – Compatible with automated extrusion systems.

Why Choose Delta Tecnic for Cable Masterbatch?

-

Technical Leadership

- Bespoke Formulations – Work directly with our R&D team for tailored solutions.

- Compliance with Global Standards – ISO, UL, ASTM certifications.

- High-Speed Processing – Designed for maximum efficiency in extrusion lines.

-

Commitment to Sustainability

- Eco-Friendly Masterbatch – Lead-free, phthalate-free, and recyclable solutions.

- Energy-Efficient Processing – Reduces carbon footprint and operating costs.

- Circular Economy Support – Encourages closed-loop recycling in cable production.

-

Industry Recognition

- Trusted by leading cable manufacturers worldwide.

- Proven expertise in high-performance masterbatches for automotive, energy, and telecom industries.

Elevate Your Cables with Delta Tecnic

In a world that depends on reliable connectivity and sustainable infrastructure, Delta Tecnic’s cable masterbatch solutions are engineered to exceed industry expectations.

Partner with Delta Tecnic to take your cable production to the next level—where precision meets innovation, and every meter of cable powers progress.